Table of content

Retailers have become multi-channel sellers and are supported by third-party logistics services to handle large volumes of small orders. Adopting IoT and automating inventories is helping them to scale operations.

Modern warehouse operations for retail and e-commerce support the fulfillment of orders from multiple purchasing channels, warehouse inventories at multiple locations, and various logistics solutions.

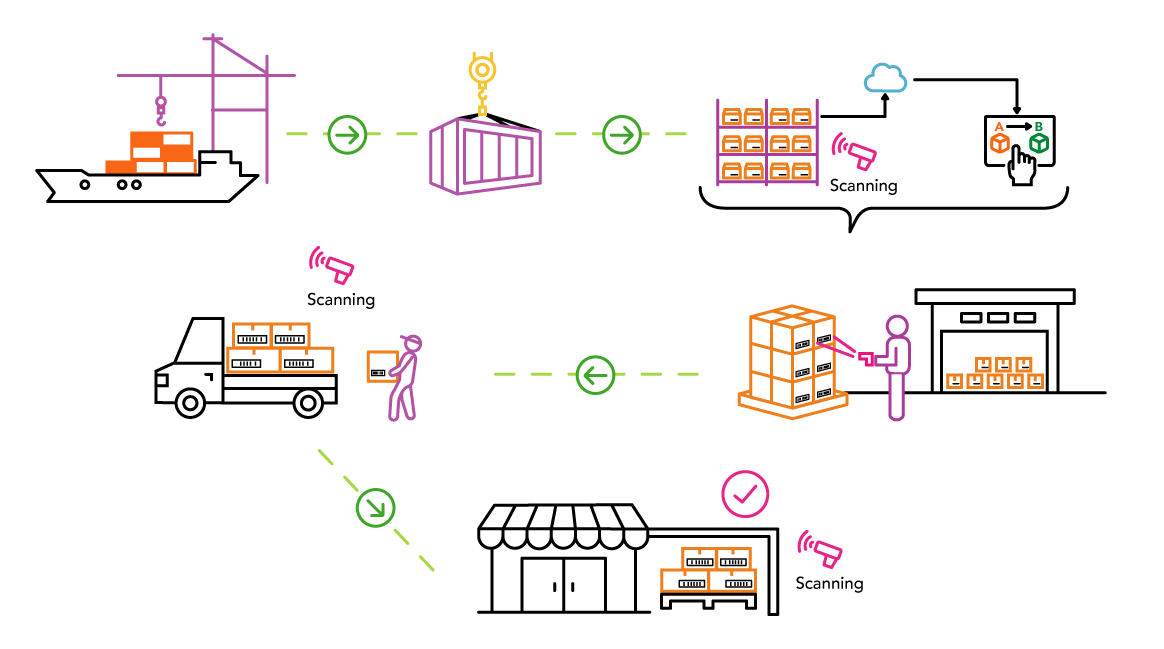

Distribution of goods involves multiple fulfillment options (B2B, B2C, drop shipping, marketplace sellers, etc.) and third-parties service providers that need visibility of inventories across the supply chain process.

IoT enables real-time inventory tracking by embedding technologies such as RFID, Barcode, BLE, and software to connect physical products with systems and transmit data. Retail and logistics systems act on this information to gain operational efficiency and reduce costs.

Therefore, smart logistics activities are enhanced when adopting IoT inventory management solutions that share data with 3PL networks, platforms, cloud solutions, and enterprise systems to fulfill demand with flexibility, scalability, and reliability.

A Need for Real-time Inventory Tracking and Management

Creating solutions for real-time inventory tracking and management and automating processes in the warehouse is a challenge for businesses.

An IoT inventory management system provides real-time information for making decisions. Businesses need a warehouse management system (WMS) interacting with order management software and other applications to efficiently manage their supply chain processes.

Installing sensors in store shelves, storage bins, and around warehouses helps to monitor the movement and use of assets, which transmits accurate information to management systems. In addition, it helps the organization adjust processes and technologies to handle large orders and speed deliveries.

Individual items are tagged with RFID tags that have encoded data about the product that readers scan and transmit the information to the cloud. The IoT system displays the real-time status, location/movement, or quantities to the application user. RFID antennas relay signals (radio waves) from the tags to readers across the building.

The IoT system is programmed to send alerts to users when an item location changes, such as if a product moves out of a geofencing area, if it is out of stock, if parts arrive to an assembly line, if items ship, etc.

IoT inventory management also applies to assets or fleets such as inventory equipment, trucks, machinery, vehicles, etc. Using GPS or 5G to monitor inventory during transport keeps track of its condition, temperatures, humidity, etc.

Inventory data provided by IoT systems are also used by machine learning/artificial intelligence software to detect patterns in the behavior of inventories and improve system functions.

Top Benefits of IoT Inventory Management (Real-Time Inventory Tracking and Management)

Knowing the location of inventories has the following benefits:

- Inventory visibility in real-time

- Integrate with ERP and other systems—order management, shopping carts, etc.

- Operational efficiency—enhance process efficiencies and time savings (labor)

- Scalability and implementations of new systems—expand new services

- Automate workloads in the warehouse—reducing manual processes

- Space utilization monitoring—optimize warehouse/store space

- Use of dashboards and analytics for decision-making

- Provide better customer service—integrate with client systems

Services that Benefit from IoT Inventory Management

Many services can benefit from IoT technologies to handle growth and scale their operations in a diversified fulfillment landscape, partnering with other 3PLs or 4PLs, adding new warehouse locations, and automating processes in the warehouse.

An inventory management system using IoT can help organizations add flexibility to their operations and become more agile, tracking assets in many locations, fulfilling orders for many customers, and many other functions. Some of the services that benefit from systems with IoT inventory management features are:

- Inventory storage

- Order pick and pack

- Order shipping & tracking

- Order returns

- Kitting and assembly

IoT Inventory Tracking Integrations

Real-time inventory tracking is integrated into a warehouse management system and other technologies to improve operational efficiency. The main systems interacting with inventory are the following:

- Warehouse Management Systems (WMS)

- Transportation Management Systems (TMS)

- Order Management Systems (OMS)

- Robotics (picking and packing)

- Electronic Data Interchange (EDI)

- Yard management

- Shopping cart connectivity

- Artificial intelligence solutions

Most organizations are adopting IoT for inventory management. However, some aspects that must be addressed include communication protocols, IoT security, and scalability. Nevertheless, the costs of IoT technologies continue to decrease, and IoT inventory management solutions keep advancing.